18 October 2011 // Press centre PJSC "AZOVSTAL IRON & STEEL WORKS"

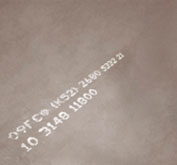

Large-scale systematic activities focused on expansion of manufactured products mix, increase of its attractiveness and quality improvement is in progress at PJSC "AZOVSTAL IRON & STEEL WORKS". Direction exhibiting the most promise is a mastering of production technology for corrosion-resistant steel, in particular, steel grade 09ГСФ.

Large-scale systematic activities focused on expansion of manufactured products mix, increase of its attractiveness and quality improvement is in progress at PJSC "AZOVSTAL IRON & STEEL WORKS". Direction exhibiting the most promise is a mastering of production technology for corrosion-resistant steel, in particular, steel grade 09ГСФ.

This steel grade is characterized by high resistance to low temperatures and hydrogen-sulfide corrosion as well as used for manufacture of large diameter pipes to be used in aggressive environment for oil transportation.

High performance of pipes made of steel grade 09ГСФ is achieved owing to three main factors: highly specialized chemical composition, low content of non-metallic inclusions and harmful impurities as well as formation of homogeneous metal structure.

Production technology for this steel grade has been developed and mastered by collaborative efforts of specialists working at Research and Technical Centre (Technical Administration) of the Works and BOF Shop. Technology is based on compliance with severe requirements to the charge and alloying materials of BOF heat as well as change in route of heat movement in the process of ladle treatment.

Today successful practical application of the technology is in progress. Produced metal is checked for compliance with the required characteristics at Corrosion Laboratory of the Works in order to certify rolled products of steel grade 09ГСФ. The achieved results show effectiveness of the developed technology for production of steel and rolled plates.

Shipment of finished products has been already started; activities on production continue.

Successful mastering of new steel grade 09ГСФ will allow PJSC "AZOVSTAL IRON & STEEL WORKS" to move to new development level and expand product mix in demand.